How do aluminum profile doors support the stable operation of glass doors in commercial spaces?

Release Time : 2025-09-22

In modern commercial space design, glass doors, with their transparent, bright, and open visual appeal, have become the preferred entrance or partition solution for shopping malls, office buildings, hotels, showrooms, retail stores, and other venues. Large expanses of glass not only enhance the space's light and airiness, but also enhance the brand's modernity and approachability. However, glass is inherently fragile, heavy, and has limited impact resistance. Without a reliable support structure, it is prone to deformation, shaking, seal failure, and even safety hazards. Therefore, aluminum profile doors serve as the "framework" and "guardian" of glass door stability. Through their high-strength structural design, precision machining, multiple sealing systems, and flexible system adaptability, they ensure long-term stable, safe, and smooth operation in high-use, large-scale, and high-load commercial environments.

1. High-Strength Aluminum Alloy: The Structural Foundation for Supporting Large Glass

Glass doors in commercial spaces are often large and heavy, especially all-glass floor-spring doors, heavy-duty sliding doors, or curtain-wall revolving doors, where a single leaf can weigh hundreds of kilograms. Aluminum profile doors, heat-treated and strengthened, possess excellent tensile strength and yield resistance. The profile wall thickness is typically at least 1.8mm, and key stress-bearing areas feature thickened or multi-cavity designs to effectively distribute concentrated loads transferred from the glass, preventing deformation or distortion. This high-strength structure ensures the door remains stable despite frequent opening and closing, the jostling of people, and strong winds.

2. Multi-Cavity Thermal Break Structure: Improving Overall Rigidity and Stability

Modern aluminum profiles commonly utilize a multi-cavity thermal break design. This design creates multiple enclosed chambers within the profile, with nylon insulation strips inserted between the inner and outer layers to form a "thermal break." This structure not only significantly improves the profile's thermal insulation performance but, more importantly, enhances its overall rigidity and torsional resistance. The multiple cavities act like "reinforcements" in a building, effectively resisting torsional deformation during door opening and closing. The thermally insulated design reduces stress caused by thermal expansion and contraction, preventing door leaf sticking or seal failure due to temperature fluctuations, ensuring long-term operational stability.

3. Precision Track and Pulley System: Ensuring Smooth Opening and Closing

For sliding and folding doors, the track system provided by Aluminum Profile is essential for stable operation. High-quality Aluminum Profile tracks utilize a one-piece molding process, resulting in a smooth, wear-resistant, and non-deformable surface. Combined with high-precision bearing pulleys or suspension systems, they ensure smooth, silent, and stable door movement. Built-in anti-slip devices and guide structures prevent the door leaf from jumping or deviating during high-speed sliding. For heavy-duty doors, dual-track or multi-wheel load-bearing designs can be used to distribute the weight and extend service life.

4. Safety Glass Fixing and Sealing System

Aluminum Profile securely secures the glass using various methods, including compression molding, adhesive strips, and structural adhesive grooves. For frameless or semi-concealed frame doors, the profile is designed with dedicated glass notches. Combined with high-strength structural adhesive and mechanical fasteners, this achieves an "invisible" glass fixation, ensuring both aesthetics and safety. Multiple sealing strips are placed between the profile and the glass, creating an airtight and watertight barrier to prevent wind and rain infiltration and effectively reduce noise. The stability of the sealing system is directly related to the long-term usability of the door.

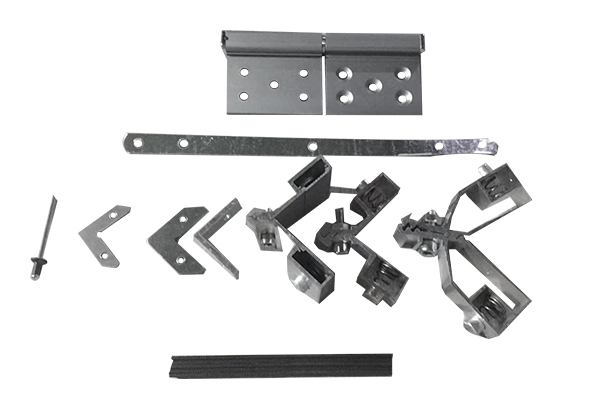

5. Compatibility with High-Strength Hardware for Enhanced Overall Safety

Commercial glass doors require heavy-duty hardware such as floor springs, door closers, multi-point locks, and sensors. The aluminum profile design incorporates standard mounting holes and reinforced structures to ensure these hardware fit securely and deliver optimal performance. For example, the floor spring seat plate is tightly connected to the bottom of the profile, evenly distributing opening and closing forces throughout the door frame, preventing localized cracking. The multi-point lock utilizes an internal drive rod within the profile for upper and lower locking, enhancing security and wind resistance.

6. Durability and Low Maintenance: Suitable for High-Intensity Use

Commercial spaces experience high traffic volume, with doors opening and closing hundreds of times daily. Aluminum profiles are powder-coated, fluorocarbon-coated, or anodized for superior resistance to UV rays, corrosion, and abrasion, ensuring long-term resistance to fading and peeling. They maintain their aesthetic and structural integrity even in humid, salt-spray, and polluted environments, reducing maintenance costs.

In commercial spaces, aluminum profile doors serve not only as a "frame" for the glass but also as the "load-bearing structure" and "stabilizing core" of the entire door system. Their high strength, precision, and durability provide a solid foundation for large, frequently used glass doors, ensuring they maintain a secure, stable, and smooth appearance while maintaining a transparent and beautiful appearance.

1. High-Strength Aluminum Alloy: The Structural Foundation for Supporting Large Glass

Glass doors in commercial spaces are often large and heavy, especially all-glass floor-spring doors, heavy-duty sliding doors, or curtain-wall revolving doors, where a single leaf can weigh hundreds of kilograms. Aluminum profile doors, heat-treated and strengthened, possess excellent tensile strength and yield resistance. The profile wall thickness is typically at least 1.8mm, and key stress-bearing areas feature thickened or multi-cavity designs to effectively distribute concentrated loads transferred from the glass, preventing deformation or distortion. This high-strength structure ensures the door remains stable despite frequent opening and closing, the jostling of people, and strong winds.

2. Multi-Cavity Thermal Break Structure: Improving Overall Rigidity and Stability

Modern aluminum profiles commonly utilize a multi-cavity thermal break design. This design creates multiple enclosed chambers within the profile, with nylon insulation strips inserted between the inner and outer layers to form a "thermal break." This structure not only significantly improves the profile's thermal insulation performance but, more importantly, enhances its overall rigidity and torsional resistance. The multiple cavities act like "reinforcements" in a building, effectively resisting torsional deformation during door opening and closing. The thermally insulated design reduces stress caused by thermal expansion and contraction, preventing door leaf sticking or seal failure due to temperature fluctuations, ensuring long-term operational stability.

3. Precision Track and Pulley System: Ensuring Smooth Opening and Closing

For sliding and folding doors, the track system provided by Aluminum Profile is essential for stable operation. High-quality Aluminum Profile tracks utilize a one-piece molding process, resulting in a smooth, wear-resistant, and non-deformable surface. Combined with high-precision bearing pulleys or suspension systems, they ensure smooth, silent, and stable door movement. Built-in anti-slip devices and guide structures prevent the door leaf from jumping or deviating during high-speed sliding. For heavy-duty doors, dual-track or multi-wheel load-bearing designs can be used to distribute the weight and extend service life.

4. Safety Glass Fixing and Sealing System

Aluminum Profile securely secures the glass using various methods, including compression molding, adhesive strips, and structural adhesive grooves. For frameless or semi-concealed frame doors, the profile is designed with dedicated glass notches. Combined with high-strength structural adhesive and mechanical fasteners, this achieves an "invisible" glass fixation, ensuring both aesthetics and safety. Multiple sealing strips are placed between the profile and the glass, creating an airtight and watertight barrier to prevent wind and rain infiltration and effectively reduce noise. The stability of the sealing system is directly related to the long-term usability of the door.

5. Compatibility with High-Strength Hardware for Enhanced Overall Safety

Commercial glass doors require heavy-duty hardware such as floor springs, door closers, multi-point locks, and sensors. The aluminum profile design incorporates standard mounting holes and reinforced structures to ensure these hardware fit securely and deliver optimal performance. For example, the floor spring seat plate is tightly connected to the bottom of the profile, evenly distributing opening and closing forces throughout the door frame, preventing localized cracking. The multi-point lock utilizes an internal drive rod within the profile for upper and lower locking, enhancing security and wind resistance.

6. Durability and Low Maintenance: Suitable for High-Intensity Use

Commercial spaces experience high traffic volume, with doors opening and closing hundreds of times daily. Aluminum profiles are powder-coated, fluorocarbon-coated, or anodized for superior resistance to UV rays, corrosion, and abrasion, ensuring long-term resistance to fading and peeling. They maintain their aesthetic and structural integrity even in humid, salt-spray, and polluted environments, reducing maintenance costs.

In commercial spaces, aluminum profile doors serve not only as a "frame" for the glass but also as the "load-bearing structure" and "stabilizing core" of the entire door system. Their high strength, precision, and durability provide a solid foundation for large, frequently used glass doors, ensuring they maintain a secure, stable, and smooth appearance while maintaining a transparent and beautiful appearance.