How do aluminum doors block out the clamor of the road?

Release Time : 2025-08-26

For families living near urban arterials, overpasses, or commercial districts, traffic noise is a major concern that impacts their quality of life. The whirring of traffic, honking horns, and the nighttime clatter of heavy vehicles often make it difficult to sleep and concentrate on work. Among the many soundproofing solutions, high-performance aluminum doors, particularly thermally insulated aluminum alloy doors and windows, are becoming a "silent barrier" against noise intrusion for an increasing number of families.

1. Core Structure: Thermally Insulated Design Cuts Off Sound Bridge Transmission

Ordinary metal doors and windows, due to their high thermal and acoustic conductivity, easily transmit external noise directly into the interior through the profile, creating an "acoustic bridge effect." Modern soundproof aluminum doors, however, commonly utilize a thermally insulated aluminum alloy structure. This structure incorporates a low-thermal-conductivity and low-sound-transmission insulation strip (usually made of PA66 nylon) embedded within the aluminum profile, completely separating the interior and exterior aluminum. This not only provides thermal insulation but also creates an acoustic "break," effectively blocking the direct sound transmission path through the metal profile, significantly reducing the transmission of mid- and high-frequency noise.

2. Glass Configuration: Multi-layer Insulated/Laminated Glass is the Mainstay of Soundproofing

The glass area of a door is typically large, serving as the primary channel for sound transmission. High-quality soundproof aluminum doors utilize double or triple-layered insulating glass, or even laminated insulating glass. Specifically:

The insulating layer (often filled with an inert gas such as argon) effectively absorbs and attenuates sound wave vibrations, particularly effective against mid- and low-frequency noises (such as the roar of traffic). Laminated glass incorporates a layer of PVB soundproofing film between the two panes. This film has high damping properties, significantly absorbing sound wave energy and providing exceptional soundproofing against sudden noises (such as horns and brakes). By properly configuring the glass type and thickness, the overall sound insulation (RW) of an aluminum door can reach 35-45 decibels, equivalent to reducing 80 decibels of road noise to below 40 decibels indoors, approaching the quietness of a library.

3. Sealing System: Multiple Sealing Layers Eliminate Gaps that Leak Sound

Even the best profiles and glass can still leak sound through gaps if they're not properly sealed. High-performance aluminum doors utilize a multi-layer sealing design, typically including:

Main Sealing Strip: Located at the interface between the door leaf and the door frame, this strip is made of age-resistant EPDM rubber, offering excellent elasticity and strong compression resilience. When the door is closed, it seals tightly, forming the first layer of sound insulation.

Intermediate Isobaric Seal: An intermediate sealing strip is installed within the sliding or swing door structure to prevent air convection and sound transmission.

Brush Seal: Used in sliding door tracks, it prevents dust and sound transmission through gaps.

These sealing strips work together to form a "maze-like" sealing structure, effectively sealing all potential sound leakage gaps and ensuring seamless sound insulation.

4. Structural Strength: High-Precision Assembly Ensures Long-Term Sealing

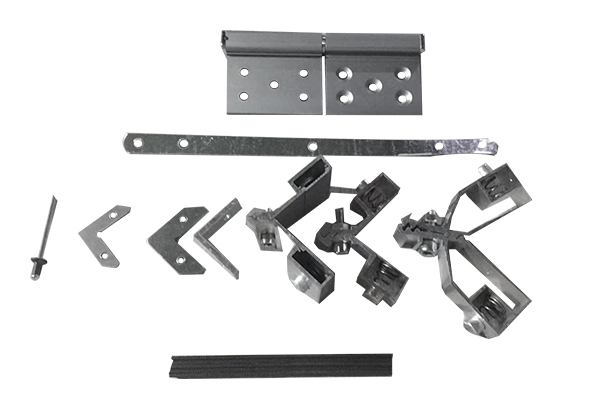

Aluminum doors are constructed from high-strength aluminum alloy profiles, precision-machined, and joined with corner brackets for a stable, resistant structure. Even with extended use and temperature fluctuations, the door frame and leaf remain flat, ensuring the seal remains in place and effective. In contrast, plastic or wooden doors and windows are prone to gaps due to thermal expansion and contraction, resulting in a gradual decline in sound insulation performance. The long-lasting stability of aluminum doors ensures their sound insulation remains effective over time.

5. Hardware System: Tight Closure Enhances Overall Airtightness

High-quality hardware, such as multi-point locking systems, allows the door leaf to lock simultaneously at multiple points when closed, ensuring uniform force distribution across the entire door body and a tight fit against the seal. This "integrated closure" method improves airtightness and sound insulation between the door leaf and frame compared to single-point locking, further reducing sound leakage.

The aluminum door's ability to effectively block out street noise isn't due to a single technology, but rather the systematic synergy of its thermally insulated structure, high-profile glass, multiple seals, robust profiles, and precision hardware. It's more than just a door; it's a scientific "sound filtering system." Choosing a high-quality, soundproof aluminum door creates a quiet barrier for your family, keeping the din at bay and bringing tranquility and comfort to your home.

1. Core Structure: Thermally Insulated Design Cuts Off Sound Bridge Transmission

Ordinary metal doors and windows, due to their high thermal and acoustic conductivity, easily transmit external noise directly into the interior through the profile, creating an "acoustic bridge effect." Modern soundproof aluminum doors, however, commonly utilize a thermally insulated aluminum alloy structure. This structure incorporates a low-thermal-conductivity and low-sound-transmission insulation strip (usually made of PA66 nylon) embedded within the aluminum profile, completely separating the interior and exterior aluminum. This not only provides thermal insulation but also creates an acoustic "break," effectively blocking the direct sound transmission path through the metal profile, significantly reducing the transmission of mid- and high-frequency noise.

2. Glass Configuration: Multi-layer Insulated/Laminated Glass is the Mainstay of Soundproofing

The glass area of a door is typically large, serving as the primary channel for sound transmission. High-quality soundproof aluminum doors utilize double or triple-layered insulating glass, or even laminated insulating glass. Specifically:

The insulating layer (often filled with an inert gas such as argon) effectively absorbs and attenuates sound wave vibrations, particularly effective against mid- and low-frequency noises (such as the roar of traffic). Laminated glass incorporates a layer of PVB soundproofing film between the two panes. This film has high damping properties, significantly absorbing sound wave energy and providing exceptional soundproofing against sudden noises (such as horns and brakes). By properly configuring the glass type and thickness, the overall sound insulation (RW) of an aluminum door can reach 35-45 decibels, equivalent to reducing 80 decibels of road noise to below 40 decibels indoors, approaching the quietness of a library.

3. Sealing System: Multiple Sealing Layers Eliminate Gaps that Leak Sound

Even the best profiles and glass can still leak sound through gaps if they're not properly sealed. High-performance aluminum doors utilize a multi-layer sealing design, typically including:

Main Sealing Strip: Located at the interface between the door leaf and the door frame, this strip is made of age-resistant EPDM rubber, offering excellent elasticity and strong compression resilience. When the door is closed, it seals tightly, forming the first layer of sound insulation.

Intermediate Isobaric Seal: An intermediate sealing strip is installed within the sliding or swing door structure to prevent air convection and sound transmission.

Brush Seal: Used in sliding door tracks, it prevents dust and sound transmission through gaps.

These sealing strips work together to form a "maze-like" sealing structure, effectively sealing all potential sound leakage gaps and ensuring seamless sound insulation.

4. Structural Strength: High-Precision Assembly Ensures Long-Term Sealing

Aluminum doors are constructed from high-strength aluminum alloy profiles, precision-machined, and joined with corner brackets for a stable, resistant structure. Even with extended use and temperature fluctuations, the door frame and leaf remain flat, ensuring the seal remains in place and effective. In contrast, plastic or wooden doors and windows are prone to gaps due to thermal expansion and contraction, resulting in a gradual decline in sound insulation performance. The long-lasting stability of aluminum doors ensures their sound insulation remains effective over time.

5. Hardware System: Tight Closure Enhances Overall Airtightness

High-quality hardware, such as multi-point locking systems, allows the door leaf to lock simultaneously at multiple points when closed, ensuring uniform force distribution across the entire door body and a tight fit against the seal. This "integrated closure" method improves airtightness and sound insulation between the door leaf and frame compared to single-point locking, further reducing sound leakage.

The aluminum door's ability to effectively block out street noise isn't due to a single technology, but rather the systematic synergy of its thermally insulated structure, high-profile glass, multiple seals, robust profiles, and precision hardware. It's more than just a door; it's a scientific "sound filtering system." Choosing a high-quality, soundproof aluminum door creates a quiet barrier for your family, keeping the din at bay and bringing tranquility and comfort to your home.