How do the size limits and joining techniques of Honeycomb door panels affect the design and realization of large custom furniture?

Release Time : 2025-04-16

The size limit of honeycomb door panel is an important factor to be considered in the design of large custom furniture. Generally speaking, the size of honeycomb door panel is limited by raw materials, production equipment and transportation. If the designed size exceeds the limit size of honeycomb door panel, it may cause deformation, cracking and other problems in the door panel during the production process. For example, in the production process of oversized door panel, the honeycomb core may not be able to support the panel evenly, thus affecting the flatness and stability of the door panel. During transportation, oversized door panels are also prone to damage, increasing transportation costs and risks. This limits the design of large-scale custom furniture in some large-size shapes. Designers need to make innovative designs within the size limit to meet customers' needs for large furniture.

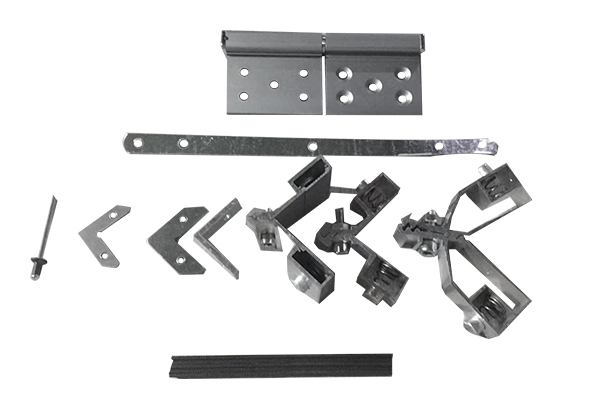

Splicing technology is a key means to solve the size limitation of honeycomb door panel and realize the design of large custom furniture. Through the splicing process, multiple smaller honeycomb door panels can be combined into a large door panel, thus breaking through the size limit of a single door panel. The splicing process can not only realize the large-scale design of furniture, but also create unique design effects through different splicing methods. For example, the use of oblique splicing, mortise and tenon splicing and other processes can add unique textures and shapes to large custom furniture, and enhance the beauty and artistic value of furniture. At the same time, reasonable splicing technology can also enhance the structural strength of the door panel, making the large door panel more stable during use.

Different splicing processes will have different effects on the design effect of large custom furniture. Common splicing processes include flat splicing and tongue and groove splicing. Flat splicing is to directly splice the edges of two door panels together. This splicing method is simple and generous, and can present an overall unified effect. It is suitable for large custom furniture designs that pursue a simple style. Tongue and groove splicing is to make concave and convex mortise and groove on the edge of the door panel. When the two door panels are spliced, the mortise and groove bite each other. This splicing method is not only strong, but also can form a natural line at the splicing point, adding a sense of refinement to the furniture. It is suitable for some design styles that focus on details and craftsmanship. In addition, there are some special splicing processes, such as curve splicing, which can achieve some unique arc or special-shaped designs, bringing more abundant shape changes to large custom furniture.

The splicing process is crucial to the structural stability of large honeycomb door panels. If the splicing process is improper, it may cause the door panel to crack, loosen and other problems during use. When choosing the splicing process, it is necessary to consider the stress condition and use environment of the door panel. For example, for large cabinet doors that are frequently opened and closed, a more solid splicing process is required, such as mortise and tenon splicing or splicing with high-strength adhesives, to ensure that the door panel can withstand frequent opening and closing actions without deformation during long-term use. At the same time, during the splicing process, attention should also be paid to the treatment of the splicing, such as sealing to prevent moisture from entering the splicing gap and affecting the structural stability of the door panel.

In the design of large-scale custom furniture, the size limit and splicing process of the honeycomb door panel need to be comprehensively considered. Designers should reasonably choose the size and splicing process of the door panel according to the specific purpose of the furniture, the design style and the needs of the customer. On the premise of meeting the design effect, the structural stability and practicality of the door panel should be ensured. For example, for large wardrobe door panels, if they are designed to be super-large in size, they may exceed the size limit of honeycomb door panels. In this case, you can consider using splicing technology to divide them into several parts for splicing, and at the same time, cover the splicing seams through clever design, so that the door panels still look beautiful as a whole. For some large furniture with high structural strength requirements, such as dining tables and desks, more attention should be paid to the selection of splicing technology to ensure that the furniture can withstand greater pressure and weight.

Although the size limit and splicing technology of honeycomb door panels have certain restrictions on the design of large custom furniture, they also bring opportunities for innovation to designers. Designers can combine honeycomb door panels of different colors and materials by cleverly using splicing technology to create unique patterns and textures, thereby making up for the size limitations. For example, using splicing technology to create a layered door panel surface, or splicing honeycomb door panels of different shapes into creative shapes, large custom furniture can be more artistic and personalized while meeting practical functions. In addition, with the continuous advancement of science and technology, new production processes and materials are constantly emerging, which also provides the possibility of breaking through the size limit of honeycomb door panel and improving the splicing process, bringing more innovation space to the design of large-scale custom furniture.

The size limit and splicing process of honeycomb door panel play a vital role in the design of large-scale custom furniture. They not only affect the structural stability and practicality of furniture, but also directly affect the design effect and artistic value of furniture. Designers need to have a deep understanding of the characteristics of honeycomb door panel and the key points of splicing process, and within the range of size limit, through reasonable selection of splicing process, realize the personalized design and high-quality production of large-scale custom furniture. At the same time, we should pay attention to the development trends of the industry and constantly explore new design methods and process technologies to promote the continuous development and progress of the large-scale custom furniture industry.